Industrial Ovens with Heat Transfer Technology

Global Finishing Solutions® (GFS) is dedicated to providing high-quality industrial spray booths to a wide variety of industries — including aerospace, automotive refinish, manufacturing and woodworking businesses. GFS strives to meet the unique needs of every customer with pre-engineered and custom solutions for paint application across the globe.

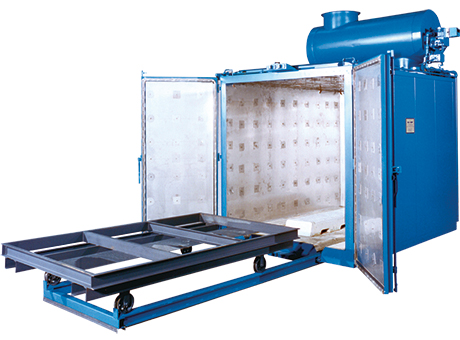

Batch Process Oven

Designed for drying, curing, baking, or preheating, Batch Process Ovens from Global Finishing Solutions® (GFS) feature excellent heat transfer technology in a compact design.

The uni-flow air distribution system circulates heated air on both sides of the industrial oven for a balanced, uniform temperature throughout the oven, resulting in a quality finish for your products.

Continuous Process Oven

Designed as part of a finishing system, Continuous Process Ovens from Global Finishing Solutions® (GFS) provide a safe, efficient finishing environment for a variety of heat applications — including paint drying, powder curing, e-coat curing, drying, and heat treating.

These modular, factory-built convection ovens are custom designed and engineered to move products through the heat zone using a variety of transport systems. Heated with gas, fuel, oil, or electricity, GFS Continuous Process Ovens operate at temperatures up to 500 degrees Fahrenheit.

Batch Burn-off Oven

Precision engineered and designed Batch Burn-Off Ovens from Global Finishing Solutions® (GFS) uses heat cleaning technology to safely and efficiently remove baked-on paint from racks, hooks, fixtures, and parts. This technology limits labor costs, minimizes environmental impact, and maximizes profit potential.

A Batch Burn-Off Oven can be used in conjunction with the Batch Burn-Off Washer, designed for secondary cleanup of burned-off racks, hooks, fixtures, and parts. Overhead and corner nozzles spray water on the part, flushing the loose paint ash from the surface.

GET A QUOTE